Description

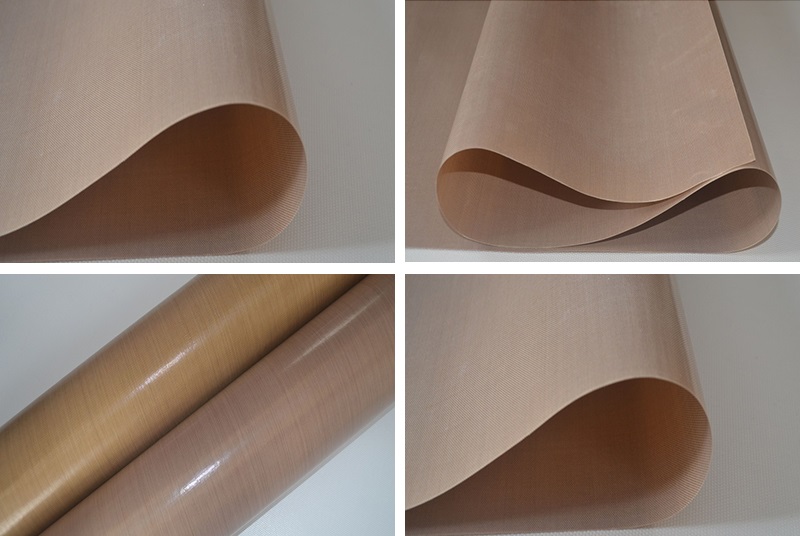

PTFE Coated Fiberglass Fabrics Sheet For Solar Photovoltaic Panels Laminator

PTFE coated fiberglass fabrics are made of high-performance glass fiber fabric impregnated with PTFE emulsion. It's designed for varieties of applications in diverse industries where high temperature, non-stick, chemical resistance, and dimensional stability characteristics.

We manufacture many styles of PTFE coated fiberglass fabrics from thickness 0.07mm to 1mm. Our PTFE coating percentages range from 15% to over 60% by weight.

PTFE Coated Fiberglass Fabrics Sheet For Solar Photovoltaic Panels Laminator

Main properties:

* High-temperature resistance(-100℉ to +550℉).

* Non-sticky and easy to clean.

* Food grade and nontoxic.

* Heat resistance and fireproof.

* Resistant to chemical corrosion, strong acid and alkali.

* Good dimensional stability, high strength, and has good mechanical properties.

* Low friction coefficient (0.05-0.1), the best choice for oil-free self-lubrication.

* Light transmittance up to 6%~13 %.

* High insulation property (the value of dielectric constant is only 2.6, and the value of tangent is less than 0.0025).

* Anti-static and Ultraviolet-proof.

Capacity and Options:

* Normal color: Brown, black or white.

* Normal Thickness: from 0.07 mm to 1 mm

* Widths: from 9mm to 4000 mm. Please see the maximum width of each style in our technical specifications.

* Roll length for roll goods: standard roll length from 10m~100m, but the roll length can be customized.

* Size of piece goods: Cut pieces according to your request.

* Anti-static or none anti-static

* Closed fabric or mesh fabric.

* With adhesive or without adhesive

* Single color or double colors of two sides.

* As an assembled transport belt, endless woven also available

Classification:

Depending on application requirements, PTFE coated fiberglass fabric can be produced with different grades.

* Common industrial grade

Coated PTFE fabric has good heat resistance, corrosion, non-stick properties, mainly used in various industrial fields.

* Standard grade

Using imported materials production, in addition to good corrosion-resistant properties, the surface is more smooth, flat, non-stick performance is good, both can be applied to general industrial applications, more advantages in some products used plastic stripping or separation sheets, gaskets, off mold surface.

* Food grade

Smooth surface, good release properties, heat resistance and easy to clean, use more secure in the food industry.

* Anti-static grade (anti-static cloth) Teflon fabric:

In addition to traditional performance of PTFE coated glass fiber fabric, adding anti static agent when producing PTFE coated glass fiber fabric, so that it has anti-static properties to meet specific customer's requirements.

Main applications:

* Heat sealing plastic film

* Gaskets & diaphragms

* Plastic ag manufacturing

* Conveyor belt

* Food drying mats and belts

* Reusable cooking tray liners

* Adhesive tape

* Welding cloth for welding and sealing; plastic film, heat sealing liner..

* Flexible compensator, friction material, wheel slice

* Anti-static cloth

Main Technical specifications:

| Model No. | Color & Feature | Thickness (mm) | Weight of Fiberglass (g/m2) ±3% | Total Weight (g/m2)±5% | Tear Strength (N/5cm) ±5% | Tear Strength (N/5cm) ±5% | |||

| Warp | Weft | Warp | Weft | ||||||

| Test Method | — | Weighing | Weighing | Weighing | HG/T2580 | GB/T 25042-B | |||

| TS015 | TS015BN | Brown | 0.14 | 105 | 300 | 1350 | 1250 | 18 | 18 |

| TS015BK | Black | 0.14 | 105 | 290 | 1300 | 1200 | 18 | 18 | |

| TS025 | TS025BN | Brown | 0.23 | 205 | 490 | 2200 | 1750 | 25 | 25 |

| TS025BK | Black Anti-Static | 0.24 | 205 | 450 | 2000 | 1700 | 25 | 25 | |

| TS035 | TS035BN | Brown | 0.32 | 255 | 620 | 3000 | 2100 | 40 | 35 |

| TS035BK | Black Anti-Static | 0.32 | 255 | 620 | 2800 | 2000 | 40 | 35 | |