Description

Silicon Rubber Rings Are Necessary Devices During Laminated Glass Pre-Laminating Process Including Pre-Heating And Pre-Vacuuming, Or Sometimes Known As Pre-Pressing.

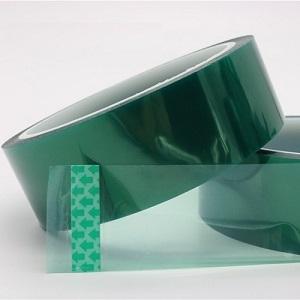

When processing laminated glass with plastic interlayer, for example, PVB interlayer, air is always trapped between two pieces of glass. The air is required to evacuate thoroughly. Or bubbles and de-lamination will be created after autoclaving. Vacuum rings are used to de-air.

Due to cost effective and flexibility, vacuum rings are one of the most popular devices to remove trapped air. Vacuum rings are usually made of extruded silicon rubber strips. Two ends are carefully joined with special skills. A silicon tube is also connected to the ring. This silicon tube is eventually connected to vacuum system. Two pieces of silicon tubes are provided with longer rubber rings used for large glass pane. Two tubes allow faster air evacuation during vacuum.

Cross section of silicon rings are specially designed such that they are easily wrapped and fix around laminated glass edges rims and are also easily removed as well. They must also be 100% air leak proof during vacuum. This vacuum process is usually done at inside ovens at high temperature. So silicon rings should also be heat resistant. Glass edges are recommended to be polished avoiding abrasive on silicon rings during wrapping and removing from glass edges. Xinology silicon vacuum rings are available in two series.

VSR-C is used for flat or bent shaped glass with curve corners and is usually applied in automotive laminated windshield.

Silicone rubber ring for glass, Silicone rubber ring for auto glass, Silicone rubber ring for laminated auto glass, Silicone rubber ring for safety laminated auto glass,

Features:

Rubber rings remove air in between two pieces of glass during pre-laminating under vacuum

Available in any lengths according to custom request

Extrusion silicon strip

Almost seamless ends joined strongly with special skills

Tough while soft for handling

Flexible enough to wrap any shape of glass turning corners

Extended silicon tube connecting to vacuum pump system

Longer vacuum rings are provided with two pieces of silicon tubes

Profile section designed to wrap and remove from laminated glass edges easily

100% air leak proof

The higher is vacuum, the tighten the seal

Carefully formulated silicon resists high temperature

Durable & long lasting

Available in two series

VSR-C for curve corners suitable of windshield

VSR-T for right angles, obtuse angles or sharp angles of trapezoid laminated glass

Special corner connecting profiles of VSR-T ensures air leak proof at angles joints

Silicone rubber ring is available in variety length or perimeter for different sizes of laminated auto glass auto clave, glass bending ovens, auto glass kilns, glass bending kilns, triplex glass ovens, laminated glass furnaces, safety glass bending furnaces.